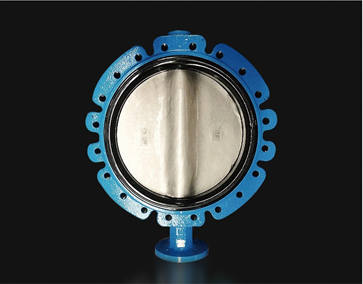

Lugged Resilient Seated Butterfly Valve

COMPANY & PRODUCTS

Butterfly Valve RBV020 Series

SISCO RBV020 series are specially designed as the line of concentric resilient seated butterfly valve, suitable for DEAD END services.

SISCO RBV020 series is designed to meet the stringent

requirements of wide range of industries worldwide. There are two different exteriors while sharing the same general and design features.

RBV020-C2 SERIES

Lug type concent ric soft backup seat w ith groove and tongue designing, size from 2” 24” (DN50-600)

RBV020-H SERIES

Lug type concentric hard backup seat designing, size from 2" 24” (DN50-600)

FIELD OF APPLICATION

Chemical

Beverage

Brewing/Wine Making

Pharmaceutica I

Food Processing

Petroleum

Transportation

Ultrapure

Water Marine

Pulp & Paper

Mining

Power/FGD

Nuclear Power

Irrigation

Water & Wastewater Treatment

Textile

Desalination

DESIGN FEATURES

Bi-directional bubble tight shut off, zero leakage.

Full EPDM lined valve interior isolating the Iine media from the body.

Dry shaft feature isolating the line media from the shaft and therefore standard shaft material can be used

Smaller operating torque.

Light weight and volume lowering cost and achieving easy installation.

Full bore feature results in higher Cv value.

GENERAL FEATURES

Body

One piece LUG style. Valve mounting top flanges meet ISO 5211 standard for direct mounting of manual operators and power actuators.

Seat

SISCO' s tongue and groove seat design lowers torque and provides complete isolation of flowing media from the body. The seat also features a molded 0-ring which eliminates the use of flange gaskets. The seat isolates the valve body and stem from

line media and has been specifically designed to seal with slip-on or weld-neck flanges.

Disc

High strength discs are casted by once, the sea ling edges are spherically machined then either hand polished or the entire disc is Nylon or Rubber coated to produce a bubble-tight shut off, minimum torque, and longer seat life. The symmetrical disc profile increases CV valves, reduces turbulence and increases pressure recovery.

Shaft

Alternative to high corrosion resistance shaft materials, RBV020 is equipped with the dry shaft design because of its concertric nature and axial sealing design where shaft with

standard material is completely isolated from the flowing media.

One shaft pin-less and double shafts pin-less design are available to be chosen depending on customers' preference. Precision machin ing of the disc and the stem connection minimizes hysteresis and produces maximum strength engagements.

Al l stem designs incorporate a blow-out proof feature.

Both disc/stem designs inherently provide complete protection from particle entrap ment and bacterial decay, protection that is required for sanitary performance. For superior erosion and abrasion resistance, the one piece disc/stem is fully encased in either EPDM Or BUNA N.

For double shafts pin-less design, precision double "D”or "Square” disc to stem connection drives the disc without the need for screws or pins. The close tolerance, double”D” 0r ”Square” connection that drives the valve disc are exclusive features of the SISCO valves. Disassembly of the shaft is just a matter of pulling the stem out of the disc.

Shaft Bushing

Non-corrosive, phenolic resin bushing absorbs actuator side thrust.

Blow-out Proof

A retaining ring, ir1stalled between the machined stem groove and gland retainer step, provides full retention of the stem in the unlikely event of internal stem failure.

Primary & Secondary Seals

These seals prevent line media from contacting with the stem or body. Primary Seal is achieved by an interference fit of the molded seat flat and the disc hub. Secondary Seal is created because the stem diameter is greater than the diameter of the seat stem hole. Self-adjusting triple 0-ring sealing is also applied to give positive sealing in both directions and prevents external substances from entering the stem bore.

Actuator Mounting

Due to a modular concept of design, all SISCO actuators including Handles, Gear Operators, Pneumatic and Electric Actuators can be mounted directly to SISCO resilient seated valves. No brackets are required, which allows of simple installation in the field, minimize possible misalignment and reduces overall height.