Introduction to and Advantages of Vacuum Butterfly Valves

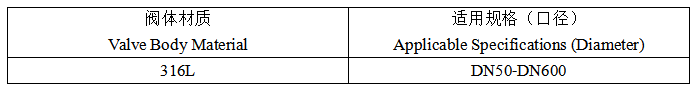

I. Applicable Diameter Ranges for Different Valve Body Materials]

Compared to ductile iron, carbon steel, cast iron, and other stainless steel materials, 316L retains excellent mechanical properties, ductility, and impact toughness while offering superior oxidation resistance, heat resistance, and corrosion resistance (particularly against chloride ion pitting).

II. Basic Parameters

Diameter: DN50–DN600

Vacuum Level: -0.1 MPa

Design Standards: 1. Side flange connections and drilling standards comply with BS EN 1092-2 PN16

2. Upper flange standard complies with ISO 5211

III. Applications of Vacuum Butterfly Valves

As a valve used in vacuum systems to isolate, connect, or control airflow direction, the vacuum butterfly valve's key feature is its reliable sealing performance under vacuum conditions. It also offers a simple structure, quick operation, high flow conductance, and easy maintenance. Common applications include the following industrial sectors:

1. Semiconductor and integrated circuit manufacturing

Since numerous critical process steps in chip manufacturing require ultra-high vacuum or high vacuum environments, this field also represents the primary application area for vacuum butterfly valves.

2. Flat panel display manufacturing

Similar to the semiconductor industry, the production of flat-panel displays such as LCD and OLED also involves numerous complex vacuum thin-film processes.

3. Solar photovoltaic industry

Thin-film solar cells are highly dependent on vacuum technology.

4. Industrial coating and surface treatment

Many industrial products require vacuum coating technology to achieve specialized surface properties.

5. Medical and biotechnology

The valve is more common in sterilization chambers and other medical equipment requiring vacuum conditions.

6. Aerospace industry

The valve is used in space environment simulation chambers, engine test equipment, satellite thermal vacuum testing systems, etc.

IV. Overall Design

The valve adopts a lug-type vulcanized butterfly valve design with a split pinless stem, offering the following advantages:

1. Bidirectional bubble-tight sealing, capable of achieving zero leakage in both directions;

2. Highly interchangeable valve stem design for simplified maintenance;

3. Low flow resistance coefficient with minimal energy consumption; large flow area design prevents clogging;

4. Effective isolation of corrosive media with excellent corrosion resistance, suitable for demanding operating conditions;

5. Flexible installation at any angle to accommodate various pipeline configurations;

6. Low operating torque enables effortless valve opening/closing, compatible with multiple drive actuators;

V. Key Design Features

1. Precision-cast valve body ensures high dimensional accuracy and superior surface finish, significantly reducing post-machining time/cost while minimizing defects like shrinkage cavities and blowholes;

2. Valve disc uses identical 316L material as valve body to maintain matched thermal expansion rates, preventing jamming while reducing electrochemical corrosion; mirror-polished surface ensures optimal seat contact;

3. The valve seat utilizes a vulcanization process, enabling adaptation to low-pressure conditions with media containing fine particles. It also features low noise and friction coefficient. The primary advantage of vulcanized valve seats is their corrosion resistance, allowing material selection based on actual working media conditions.

4. The valve stem employs a two-piece pinless design (upper/lower sections), fundamentally eliminating leakage paths compared to pinned connections. This design ensures uniform stress distribution without concentration points, providing greater load capacity and fatigue resistance while enabling easier stem installation/removal to significantly reduce maintenance downtime costs.

5. The valve incorporates bushings on both valve seat sides and the upper flange. The valve seat bushings ensure stem alignment to prevent jamming, extending seal lifespan, while the flange bushing prevents direct stem-to-body contact to reduce stem maintenance costs.

6. The upper flange face features a shaft retaining ring, gasket, and split collar assembly, providing dual protection against stem disengagement. The split collar serves as the primary safeguard, and directly locks the valve stem. The gasket distributes the thrust force, while the shaft retaining ring serves as the secondary safeguard to more effectively prevent valve stem disengagement. This system features easy installation/removal, low replacement cost, excellent protection performance, and serves as a secondary seal with high cost-effectiveness.

7. The pneumatic actuator is equipped with a positioner for clearer valve status indication, enabling easy identification even in space-constrained or poor visibility conditions.

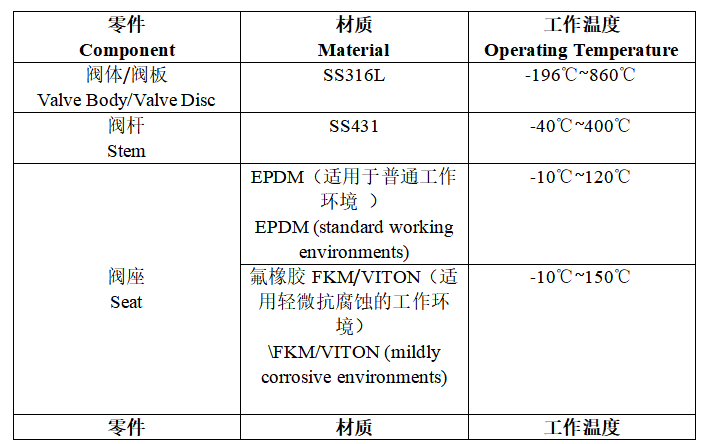

VI. Operating Environment, Material and Temperature Reference