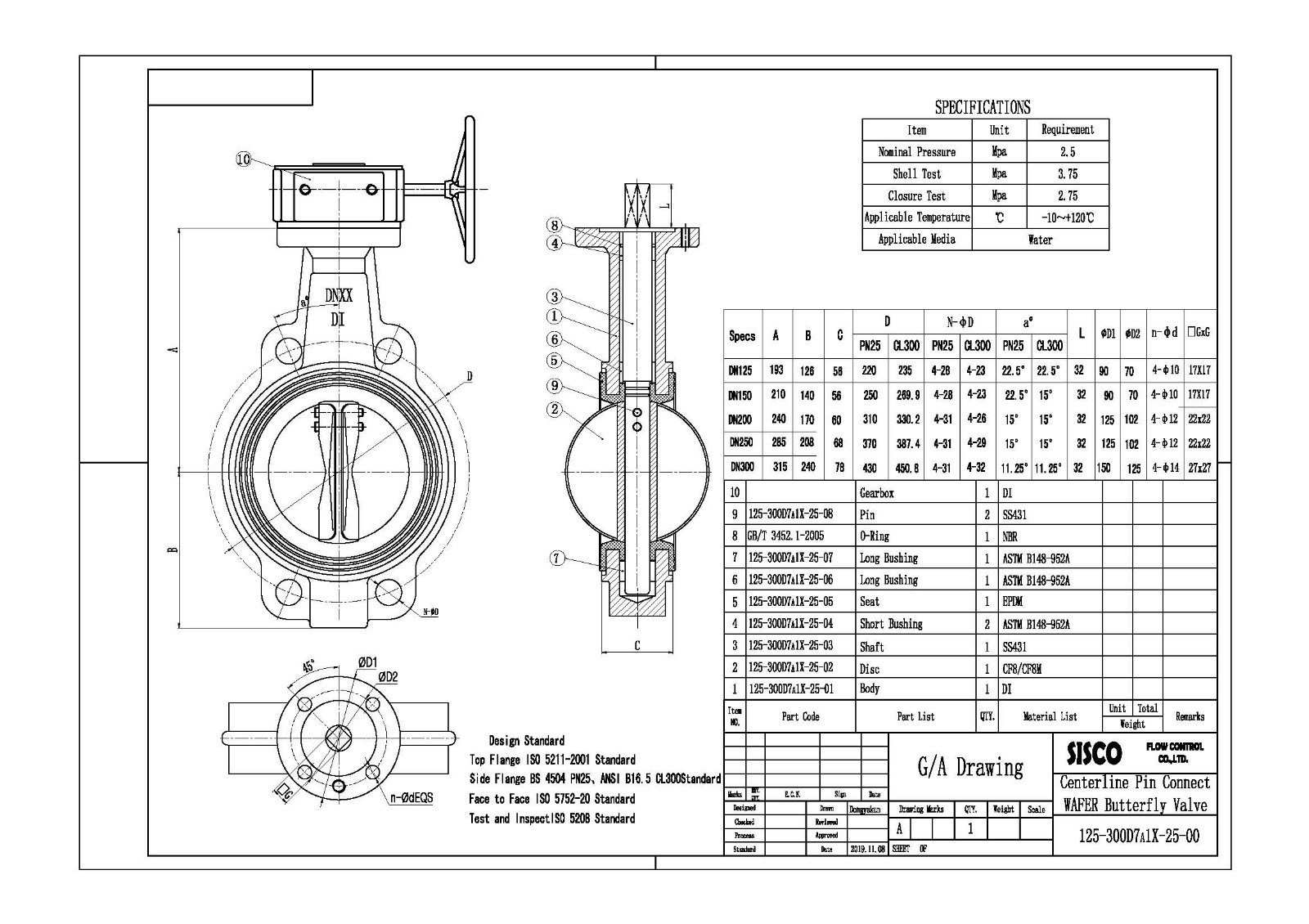

High Performance Concentric Resilient Seated Butterfly Valve

FIELD OF APPLICATION

Size

DN50-DN300

Working Pressure

2.5Mpa, ANSI Class300

End connection

BS EN 1092-2 PN25, DIN2634 PN25, ASME/ANSI B16.5 CLASS300

Face to face

IS05752-20,BSEN558

RBV-S/PN25 series are the self-developed and high preformed concentric resilient seated butterfly valve that perform reliably under working pressure of 25 bar(PN25).

The design breaks through the standard pressure limitation (max PN16) for concentric resilient seated butterfly valve to replace traditional eccentric PN25 butterfly valve. Along with concentric design features such as dry shaft and body, low torque, low weight, bi-directional installation etc., working pressure up to PN25 extends valve application scope to a whole new level.

Being tested 1.5 times working pressure for sealing and 5 times working pressure for body shell strength, this series provides reliable sealing performance and service life under pressure of 25 bar.

DESIGN FEATURES

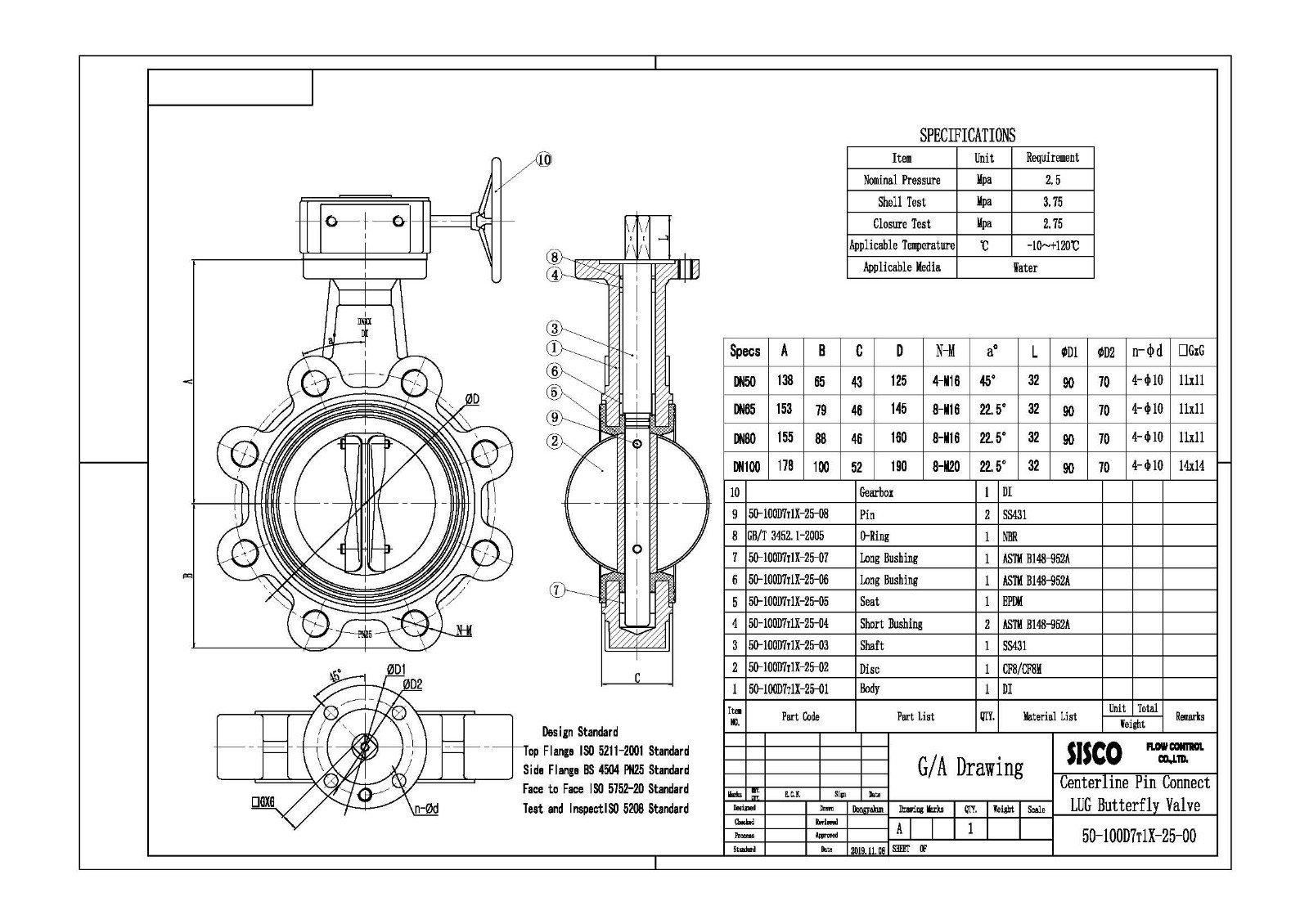

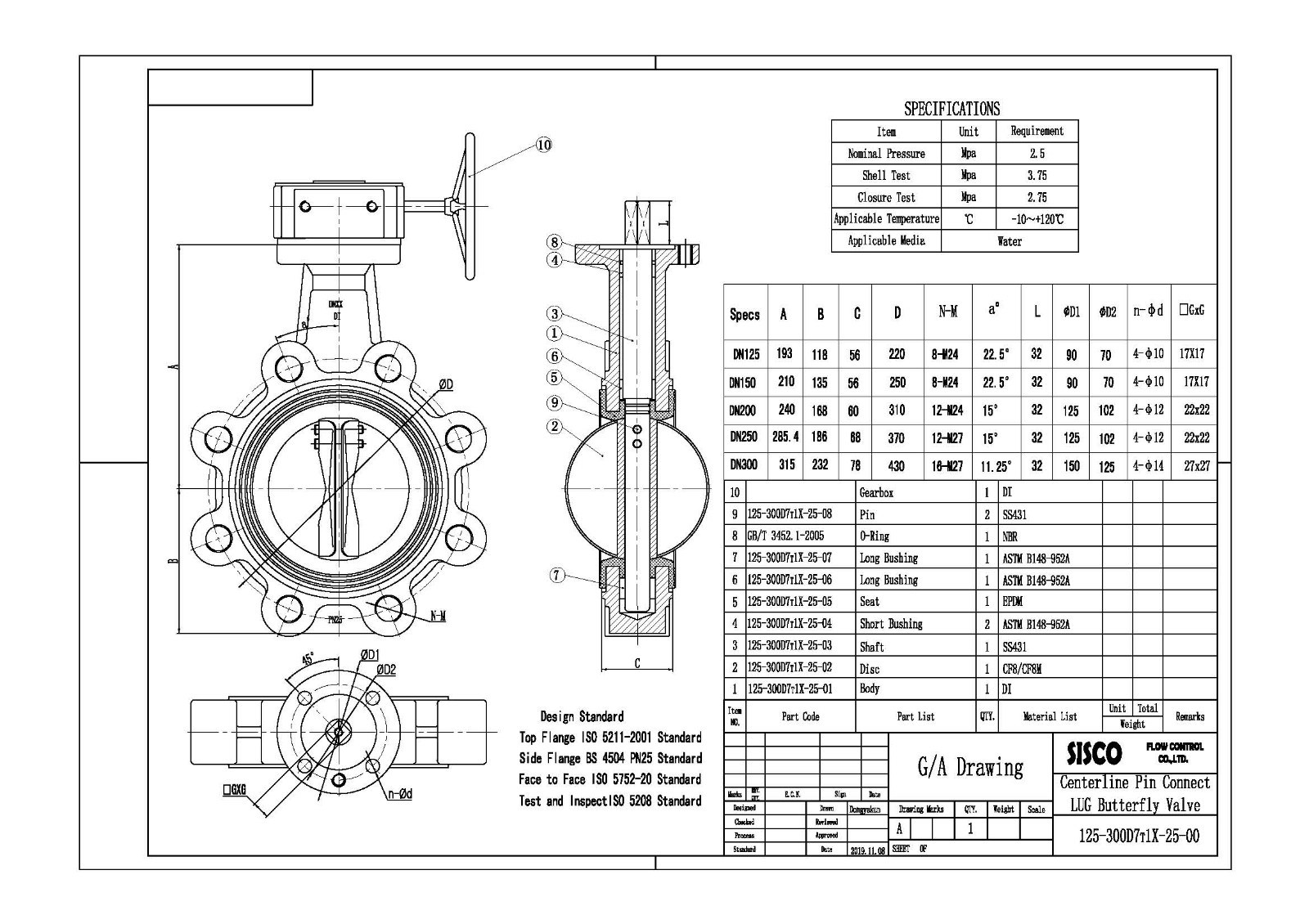

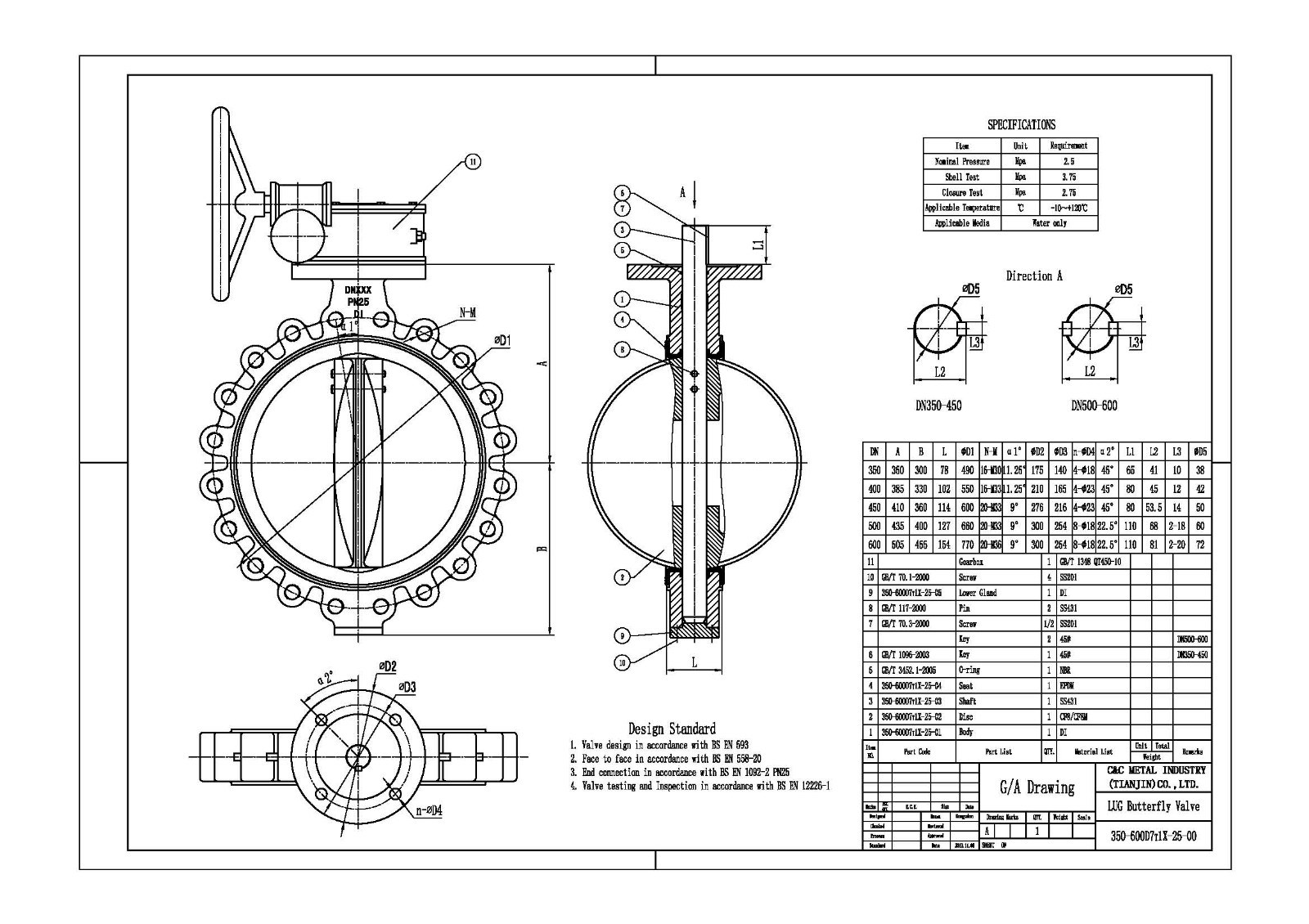

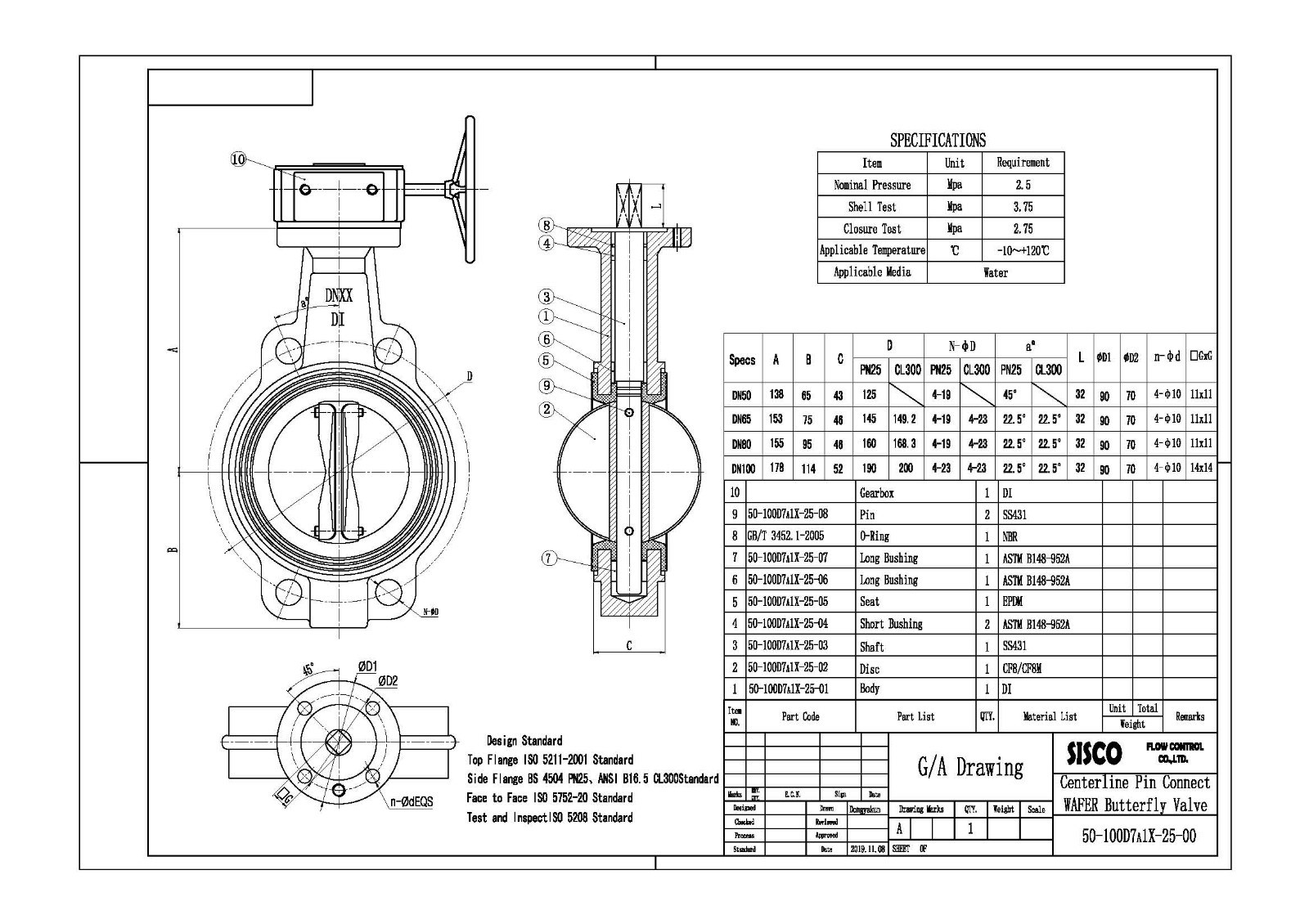

RBV-S/PN25-W SERIES

Wafer type concentric soft backup seat designing, size from 2”-12〃(DN50-DN300)

Lug type concentric soft backup seat designing, size from 2〃-12〃(DN50-DN300)

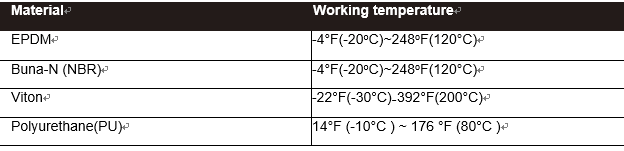

Change different material of seat, RBV-S/PN25 adapt to wide range of temperature.

Different Disc/Seat martial combination in this series are available to be chosen according to different media and working conditions, experience senior SISCO engineers are here to serve you providing professional advices to meet your particular requirements

| Parts Name | Material |

| Body | Ductile Iron WCB,CF8/CF8M |

| Surface Coating | Epoxy Coating |

| Disc | CF8/CF8M Super Duplex Stainless Steel Aluminum Bronze |

| Shaft | 431 Stainless Steel Super Duplex Stainless Steel Monel Metal |

| Seat | EPDM Buna-N(NBR) Viton Polyurethane(PU) |

GENERAL FEATURES

International Compatibility / Bi-directional Sealing

Full Rubber Lining / Dry Shaft Design

Smaller Operation Torque

Easy Installation & Maintenance

Full Bore Feature

International Compatibility

Top Flange: RBV-S/PN25 series top flanges mounting meets IS05211 standard for direct mounting of handles, gear operators, pneumatic and electric actuators, and no brackets are required, which allows of simple installation in the field, minimizes possible misalignment and reduces overall height Side Flange: Connection compatibility design allows this series butterfly valve to be installed between flanges of BS EN 1092-2 PN25, DIN 2634 PN25, ASME/ANSI B16.5 CLASS300 simultaneously.

Bi-directional Sealing

Concentric resilient seated design features the series bi-directional bubble tight shut off with zero leakage, bi-directional sealing breaks the directional limitation during installation, making it much more flexible and more achieving friendly working, zero leakage perfects the sealing performance especially in gas and air application.

Full Rubber Lining

Full Rubber lined valve interior completely isolating the line media from the body eliminating unnecessary contacts between media and body, body material therefore does not have to be corrosion resistance materials, which usually being expensive, this feature lowers the overall cost.

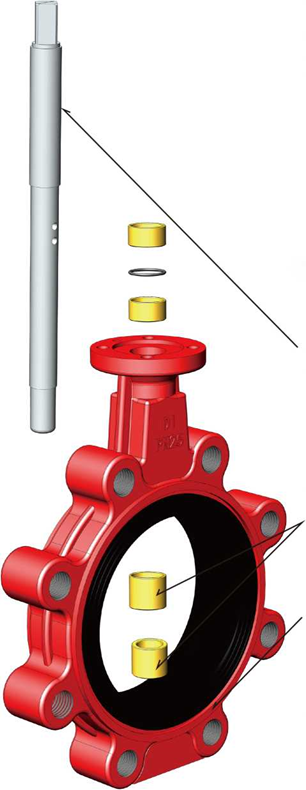

Dry Shaft Design

Alternative to high corrosion resistance shaft materials, this valve is equipped with the dry shaft provision, in that case the shaft with standard material is protected from the medium by applying rubber lining, and this lining protects the standard shaft material against corrosive environments.

Smaller Operating Torque

Disc of precise calculation, interference fit of seat and polishing disc sealing surface greatly reduces the operating torque, thus closing torque which makes operation easier as well as saving cost in actuator selection.

Easy Installation & Maintenance

Light weight and volume lowering cost and achieving easy installation

Full Bore Feature

Full bore feature results in extremely higher Cv value and minimized the flow loss.

Thickened and high intensity disc makes RBV-S/PN25 series reliable under PN25 working pressure and while blocking the medium. Streamline and dumbbell-shaped disc can maximize the CV and minimize the resistance with increasing the intensity.

The sealing edges are spherically machined, and then hand polished to provide minimum torque and longer seat life. SISCO also provide mirror polished disc to lower flow and operation torque and increase Cv value.

Seat

SISCO's vulcanized tongue and groove seat with spherical sealing design is the key to reliable seal under PN25 working pressure. As our core and patent seat designing, this nontraditional spherical seat design makes RBV-S/PN25 series of high performance centerline butterfly valves perform excellent under PN25.

There is a sealing zone in the middle of the seat. The disc can seal well as long as within the seal zone which means that being vertical to seat is not the only way of seal.

Double water line design at each edge can form a vacuum space to absorb and make seal between butterfly valve and pipes effective while valve is mounted.

Both wafer and lug type of RBV-S/PN25 serie have passed the seal test of 38 Bar(1.5 times of working pressure).

The disc 〇.D. clearance is designed to work with all standard piping.

Blow-out Proof

Reliable blow-out proof provides full retention of the shaft in the unlikely event of internal shaft failure. According to connection difference between shaft and disc there are two kind of blow-out proof designing as below:

Non-pin connection

blow-out proof Pin connection

blow-out proof

Shaft

One unique shaft without any groove on it so that minimized hysteresis and produces maximum strength engagements.

Single shaft pin-less disc connection and single shaft pin disc connection are both available to be chosen according to customers' preference.

Shaft Bushing

Using bronze alloy bushing to keep self-lubricating nature, absorbs actuator side thrust in the meantime, provides additional support for the shaft.

Body

We offer WAFER and LUG type so that could be mounted in the middle or the end of the pipe. One-piece structure casted by high standard ductile iron material, both wafer and lug type of RBV-S/PN25 series have passed the shell test of 125 Bar(5 times of working pressure).