PTFE Resilient Seated Butterfly Valve

PRODUCTION CAPABILITY AND CERTIFICATE

FIELD OF APPLICATION

Chemical

Beverage

Brewing/Wine Making

Pharmaceutical

Food Processing

Petroleum Refining &Oilfield

Transportation

Ultrapure Water

Marine

Pulp & Paper

Mining

Power/FGD

Nuclear Power

Irrigation

Water & Wastewater Treatment

Textile

Desalination

DESIGN FEATURES

1.Bi directional bubble tight shut off ,zero leakage.

2.Full PTFE cladding design of the seat thoroughly prevent pipeline media from corroding body, body connected surface and disc.

3.Dry shaft feature isolating the pipeline media from the shaft and therefore shaft with standard material can be used.

4.Split Body Design achieves fiexible torque control.

5. Light weight and volume lowering cost and achieving easy instal lation.

6.Full bore feature results in higher Cv value.

GENERAL FEATURES

Body

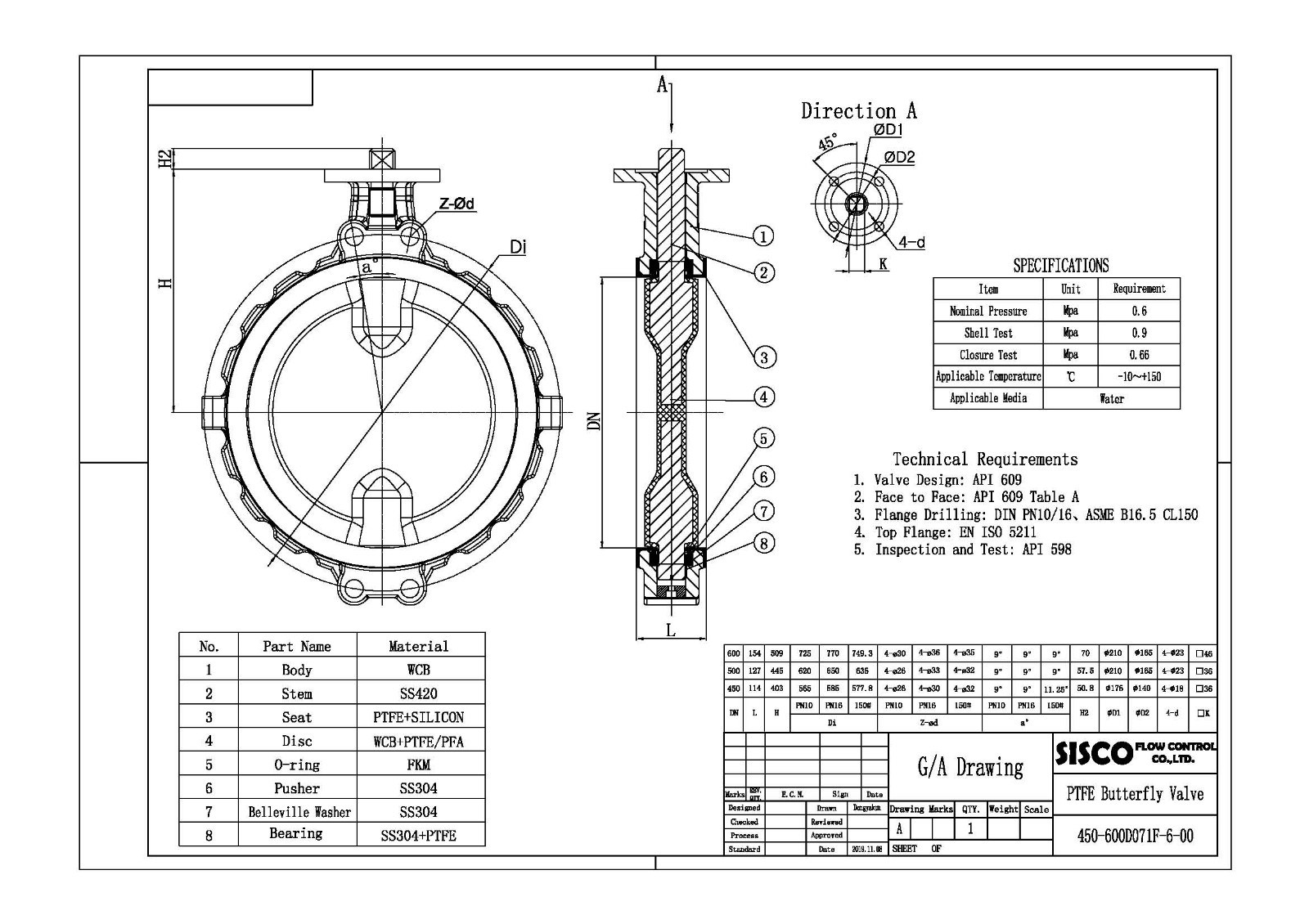

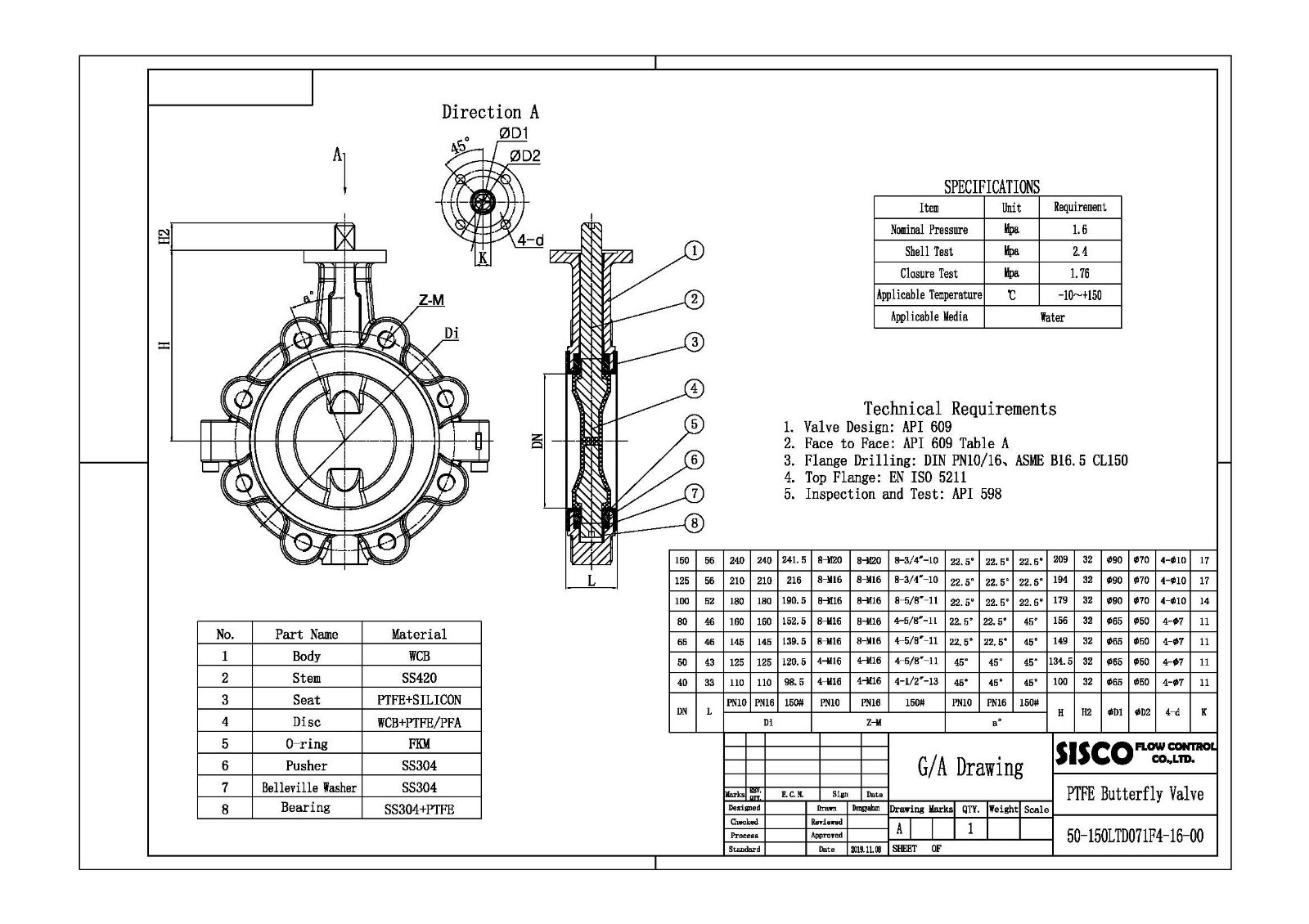

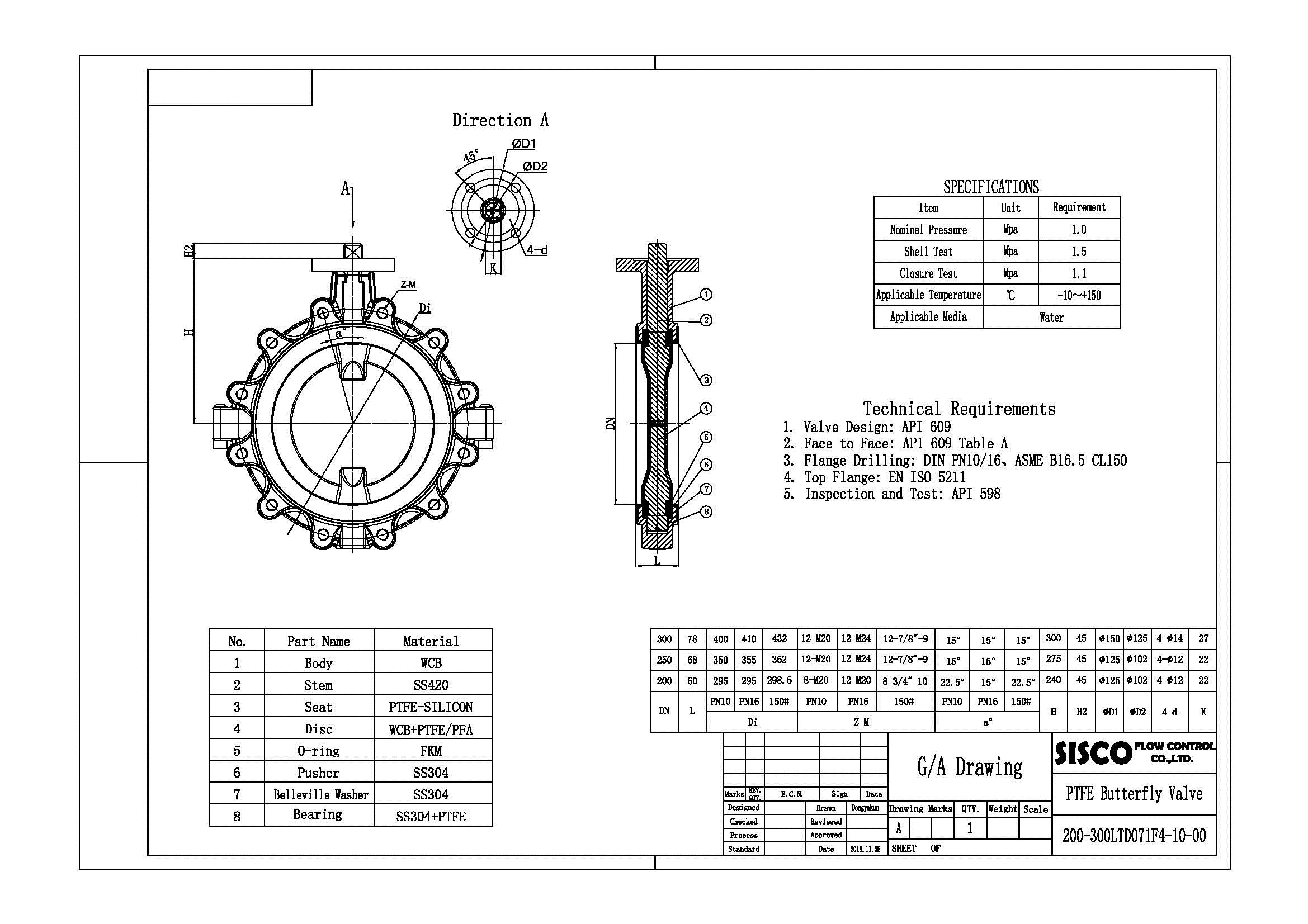

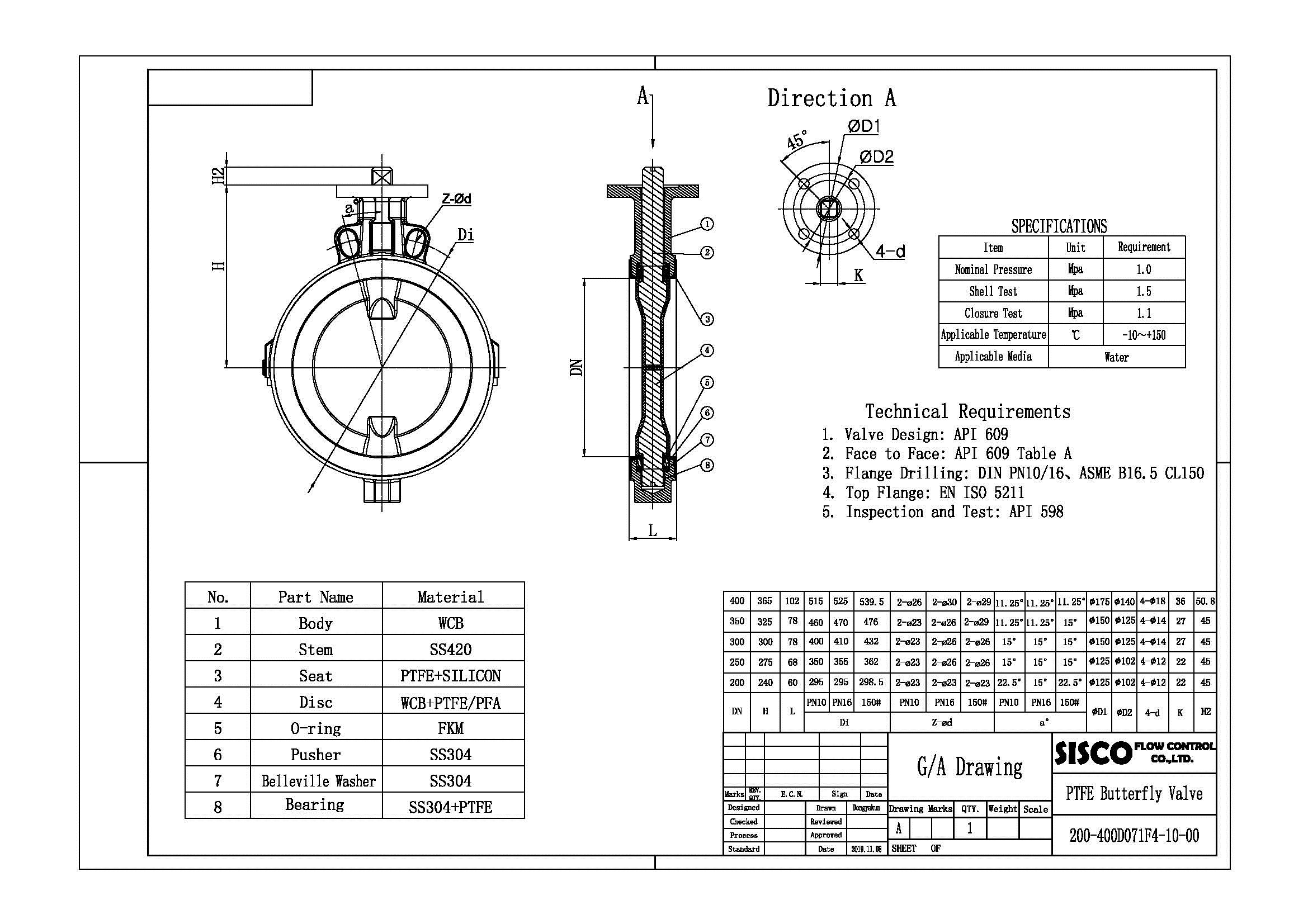

Split body design contains adjustable clearance between upper & lower bodies and ad justing bolts, which is able to, according to actual need, effectively improve sealing effec tiveness, control torque and increase service life of the seat and disc. Al l bodies are drilled to be compatible with DIN PN 1 0, DIN PN 1 6, and ANSI 150 simultaneously. Top flange meet with ISO 521 1 standards for direct mounting of manual operators and actuators.

Seat

SISCO RBV060 Series uses PTFE+SI LICON or PTFE+F KM double-layer compound seat, a complete SILICON or FKM-made layer is as a seat energizer between the seat and body, which not only makes up the poor resilience of the PTFE material, but enhances the sealing efficiency of the valve. RBV060B Series adopts PTFE coated disc and body contact face, the design thoroughly prevent line media from corroding body, body contact face and disc, and greatly increase lifetime of the valve.

Disc

The high-strength once-casting-molding disc is fully coated with PTFE materials, com pletely isolates the line media from the disc and shaft, and achieves most excel lent and comprehensive sealing and anti-corrosion. The customized disc exactly matches full PTFE coated seat, combined with torquead- justable split body design ,which avoids the increase of the torque value caused by PTFE coating, and makes SISCO RBV060B Series possesses lower torque valve and better sea ling to com pare with the product s of same kind.

Shaft

Alternative to high corrosion resistance shaft materials, RBV060B is equipped with the dry shaft design because of its concentric nature and axial sealing design, where shaft with standard material is completely isolated from the flowing media.

Double shafts pin-less design is available to be chosen depending on customers' preference. Precision machining of the disc and the stem connection minimizes hysteresis and produces maximum strength engagements.

All stem designs incorporate a blow-out proof feature.

Connection between shaft and disc are welded, then coated with PTFE, so shaft and disc are a whole piece. This design avoid leak age caused by deformation of disc and shaft, and extremely enhance the strength of disc and s haft. Both disc/stem designs inherently provide complete protection from particle entrapment and bacterial decay, protection that is required for sanitary performance. For superior erosion and abrasion resistance, the One-piece disc/stem is fully encased in either EPDM or BUNA-N.

For double shafts pin-less design, Precision double "D" Or"Squa re” disc to stem connection drives the disc without the need for screws or pins. The close tolerance, double "D" Or"Square" connection which drives the valve disc are exclusive features of SISCO valve.

Blow-out Proof

A retaining ring, installed between the stem groove and gland retainer step, provides full retention of the stem in the unlikely event of internal stem failure .

Primary & Secondary SEALS

These seals prevent line media from contacting with the stem Or body. Primary seal is achieved by a molded o ring between disc and seat. Secondary Seal is created by the completed connection between disc, shaft and seat, they shall be a whole piece. Self-adjusting O-ring sealing is also applied to live positive sealing in both directions and prevents external substances from entering the stem bore.

Actuator Mounting

Due to a modular design, all SISCO actuators including Handles, Gear Operators, Pneumatic and Electric Actuators can be mounted directly to SISCO resilient seated valves, no brackets are required, which allows of simple installation in the field, minimizes possible misalignment and reduces overall height.