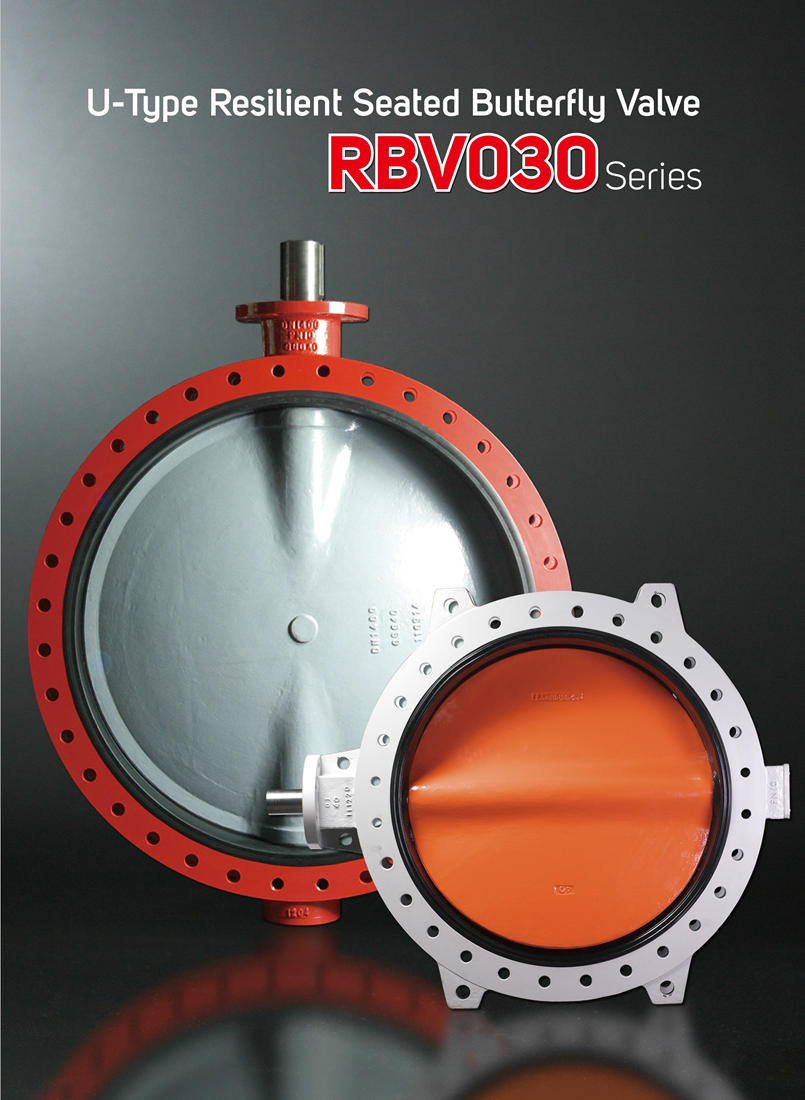

U-Type Resilient Seated Butterfly Valve

PRODUCTION CAPABILITY AND CERTIFICAFE

FIELD OF APPLICATION

Chemical

Beverage

Brewing/Wine Making

Pharmaceutical

Food Processing

Petroleum Refining& Oilfield

Transportation

Ultrapure Water

Water & Wastewater Treatment

Marine

Pulp & Paper

Mining

Power/FGD

Nuclear Power

Irrigation

Textile

Desalination

DESIGN FEATURES

1.Bi directional bubble tight shut off , zero leakage.

2.Full EPDM lined valve interior isolating the pipeline media from the body.

3.Dry shaft feature isolating the pipeline media from the shaft and therefore standard shaft material can be used.

4.Smaller operating torque.

5.Light weight and volume lowering cost and achieving easy instal lation.

6. Full bore feature results in higher Cv value.

GENERAL FEATURES

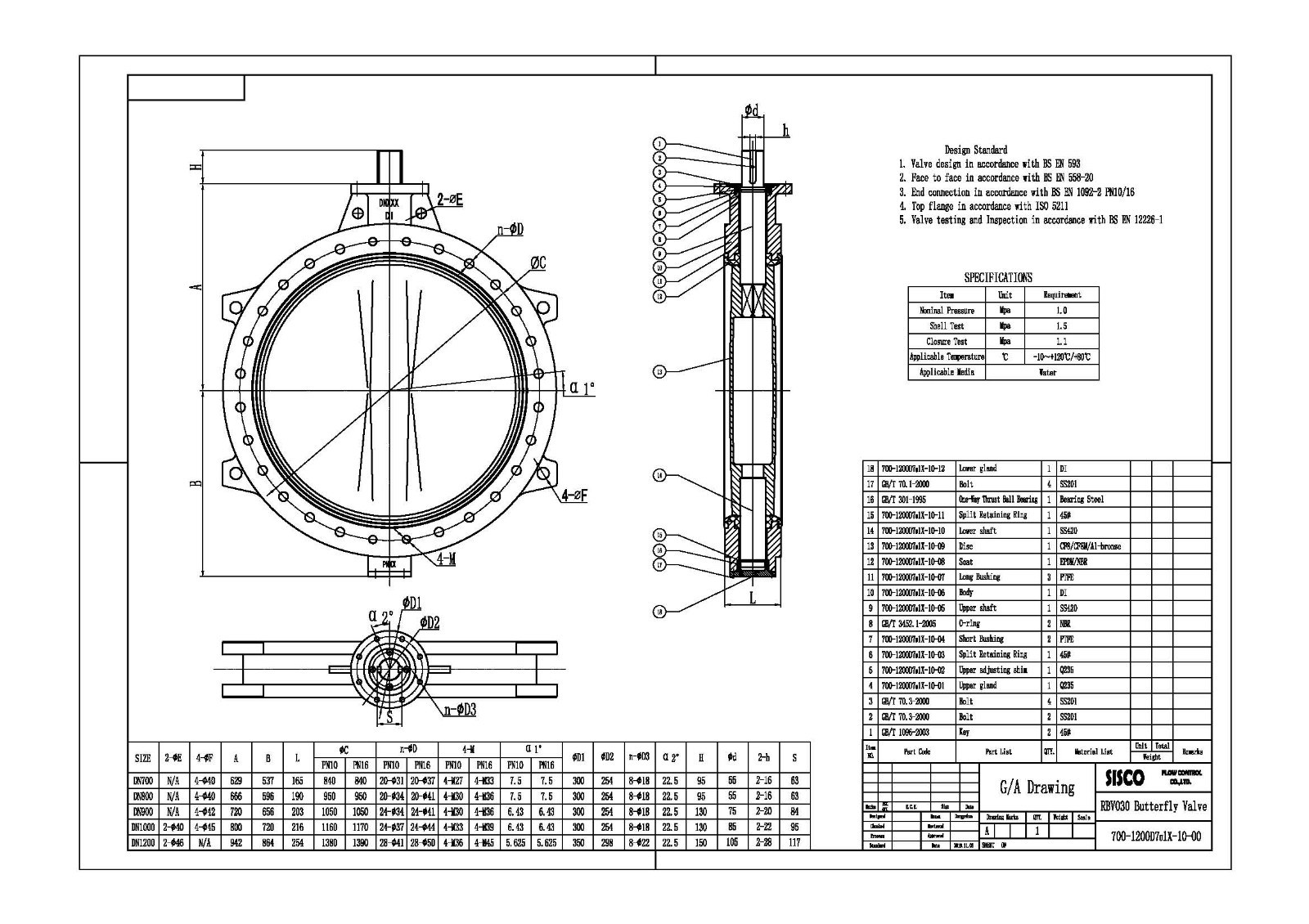

Body

One piece full double flanged style. All bodies are drilled to be compatible with AWWA C207, ANSI B 16.1, ASME 125/150, PN 10 0r other international flange standards.

Seat

The replaceable tongue and groove resilient seat ensures lower torque and provides complete isolation of flowing medium from all valve components (excluding the disc) by a totally encasing design. Molded seat 0-ring provides seal between valve and pipe flanges which eliminates requirements of flange gaskets. EPDM is the abbreviated name for Ethylene Propylene Diene Monomer. In general industry, one may see other abbrevi ations or trade names used in lieu of EPDM such as EPT, Nordel, ECD, or EPR. Typically these are the same materials as EPDM. EPDM is a standard seat material offered in SISCO resilient-seated butterfly valves. It is the most universal and economical of seat materials offered by SISCO; that is, it may be used in a wider range of applications than BUNA-N.

Disc

The high strength casting discs are casted by once, the sea ling edges are spherically machined, and then han polished to pro-vide 360°concentric seating bi-directional bubble-tight shut off, minimum torque and longer seat life. The symmetrical disc profile enhances valve performance by increasing the Cv valves, reducing turbulence and increasing pressure recovery. The disc O.D. clearance is designed to work with all standard piping.

Shaft

Alternative to high corrosion resistance shaft materials, RBV030 is equipped with the dry

shaft design because of its concentric nature and axial sealing design, where shaft with standard material is completely isolated from the flowing media.

One shaft pin-less and double shafts pin-less design are available to be chosen depending on customers' preference. Precision machining of the disc and the stem connection minimizes hysteresis and produces maximum strength engagements.

All stem designs incorporate a blow-out proof feature.

Both disc/stem designs inherently provide complete protection from particle entrapment and bacterial decay, protection that is required for sanitary performance. For superior erosion and abra sion resistance, the one-piece disc/stem is fully encased in either EPDM Or BUNA-N.

For double shafts pin-less design, precision double "D" or "Square”.

Stem Bearing

Upper and lower heavy wall sleeve self-lubricating bearings (PTFE Or bronze) are utilized to absorb actuator side thrust and minimize bearing friction torque.

Vertical Thrust Bearing

A bronze axial thrust bearing carries the disc weight when installed with shaft in vertical position and eliminates disc displacement due to the weight of the stem and disc.